Round Tube Finishing is an increasing need for manufacturers in many diverse markets. To attend these needs, NS Máquinas has been developing, and joined now to their portfolio, the largest planetary finishing machine, ML350. This machine can work with tubes from OD60mm up to OD356mm.

The concept

of planetary system: the abrasive belts rotate around the tube while the

feeding rollers are transporting it through the finishing stations of the

machine. All ML machines are equipped with this system.

Unlike the

centerless system, the planetary concept grants almost no vibration and keeps

the temperature to a minimum, preventing material distortion and ensuring a

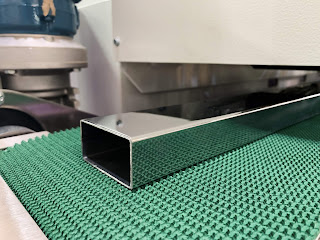

better-quality finishing. It is also possible to finish different shaped tubes,

like oval, conic, being them drilled or tapered.

ML350 is

born from the need to finish long, large diameters tubes. It’s a one-of-a-kind

machine, helping companies being more automated in the finishing process. The

reasoning behind the machine is to accomplish the joint venture between a

perfect looking finishing, and the safety of the operator.

To feed

these large tubes into the machine, two motors with 0.37kW on each side are

being used, ensuring enough strength to transport tubes up to 600kg and a

two-direction feeding system. While feeding the tube into the machine, ML350

has a photocells system to open the abrasive belts when the tube is entering

the orbital wheel, allowing a lifetime increase of this polishing consumable.

The 5.5kW motor puts the orbital wheel spinning around the tube and the 15Kw

motor runs the 120x2300mm long abrasive belts, making them go up to 25m/s. The

large measures of the abrasive belts result in a larger point of contact with

the tube, leading to more material removed and less time spent replacing

consumables.

And then… things get interesting. ML350, like its younger brother ML300, joins the free belt system (common to all ML machines) with a double pressure roller: Flexibility to cope with out-of-round tubes and stock removal in one finishing machine. The abrasive belts are supported by a double system of 3+1 rollers. 3 main rollers – one to run the abrasive belt, another for diameter adjustment, and the last one for belt tensioning. Then the pressure roller that works as an automatic contact roller. This roller will apply pressure on the tube, enforcing the removal of more material. In the end, the worker can choose whether to use it or not and its tension and the abrasive belt’s flexibility. The result? The grinding pressure you would get with 2 contact grinding rollers (one assembled on each abrasive belt) and the beauty of the planetary system where tube does not spin.

But things

don’t end here. With the combination of photocells and a user-friendly

programmable software, internally developed, it’s possible to work in 2

different automatic modes: automatic standard and automatic with repetition. In

the standard mode, the abrasive belts open automatically for tube entrance,

close tight to the tube to make pressure and open just on the very extremity of

the product, allowing a complete automatic tube finishing. The automatic mode

with repetition allows the tube to pass through the orbital wheel as many times

as programed, until reaching the desired finishing. This can be used for high

rates of material removal or whenever a fine finishing is required. In this

mode, the worker is free to do other jobs while the machine does the work it

was programmed for. All the programs can be stored and saved for future uses,

making the change of diameters and types of work easier than ever.

Together

with this, ML350 features an energy saving mode also, with automatic start and

stop. The motors are turned on when needed and turned off automatically as soon

the machine detects there is no tube inside. More, the machine shuts down

completely after five minutes of inactivity, avoiding unnecessary energy waste.

Finally, in

order to increase the machine autonomy, NS MÁQUINAS has been developing and

supplying a large number of solutions for tubes automatic loading and

unloading. Conveyor systems or bundle type and be integrated to any ML tube

finishing machine, including ML350. On the conveyor concept, operator feeds the

table with tubes, one by one, being the separated individuate with physical

barriers. This method ensures there is no undesired scratches after finishing.

On the other hand, the bundle type enables loading and unloading the tubes in a

group, leading to great savings in handling and processing time. These loading

and unloading systems will increase the time the machine works automatically

without any type of intervention, releasing the operator from heavier tasks and

contributing also to a higher safety level.

Having all

of this, the ML350 is an all-in-one machine that ensures automatization,

safety, and a consistent finish in large diameters, long and heavy tubes.