Mirror polishing is the process after

grinding and soft polishing. It starts with a good initial finishing of

the metal parts. Considering this, it is important to have a machine suitable

for your work requirements. NS Máquinas have a variety of machines for

the grinding and polishing process: Rectangular Tubes and Flat Bars Finishing

Machines. The grinding machines have capacity from 120mm width up to

1100mm, wet or dry versions, different configurations of the abrasive belt

and abrasive brush stations and a lot of automatic

options.

Considering this, we suggest three different machines for the preparation of the surface of the metal parts:

- FC120 ZK: up to 120mm

width; dry operation; one abrasive belt station +

one abrasive brush station; ideal for small workshops;

- FG330 2ZK: up to 330mm width; dry

operation; two abrasive belt stations + one abrasive brush station; high

width capacity and flexibility with 2+1 stations configuration;

- FGW330 3Z: up to 330mm width; wet

operation; three abrasive belt stations; effective machine for

intensive work and fast grinding/polishing process.

It is critical to test and configure the machines with the proper abrasive belt grits for each type of material and consider the required end result. In those cases, should be used a process with a grit at least until 320, although higher grits allow a better mirror polishing results.

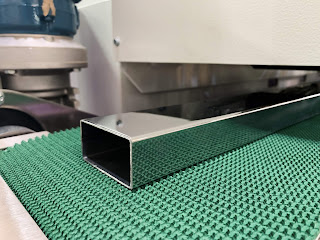

The PP220 2K is a rectangular tubes mirror polishing machine which is also suitable for flat bars mirror polishing. The machine uses a through feed system combined with two polishing wheels stations.

The conveyor belt has a 220mm width capacity which is suitable for almost all types of rectangular/square tubes and flat bars. This capacity and design additionally allow to process several tubes at the same time depending on the width of each one.

The polishing

wheels have 400mm diameter and 220mm width dimensions which

will decrease the exchange time. It is possible to utilize

diverse types of brushes such as: scotch brite, lamella, sisal or

cotton buff. Each mirror polishing station is completely

independent. The pressure can be adjusted manually by

a wheel with an accurate thickness meter of 1/10mm adjustments. In

order to achieve the mirror polishing, liquid compound should be used

simultaneously with the adequate polishing wheels. Each station includes a

45-liters tank for the liquid compound (for cut motion or color motion). Tanks are connected to

a spray gun in each station and controlled in the touchscreen panel (by

a timer).

The touchscreen panel included in the machine controls the polishing wheels speed, polishing discs oscillation on/off, conveyor belt speed and monitor motor consumption.

Consequently, this mirror polishing machine gives a high-quality gloss mirror polishing to the rectangular tubes, flat bars and other flat metal parts.

If you need more help

choosing the best machine for you, please check our machine simulator: Find a Product. Nevertheless, if you

need direct contact please send an email to marketing@nsmaquinas.pt or contact

us through one of the contacts in the contact page: Contacts.